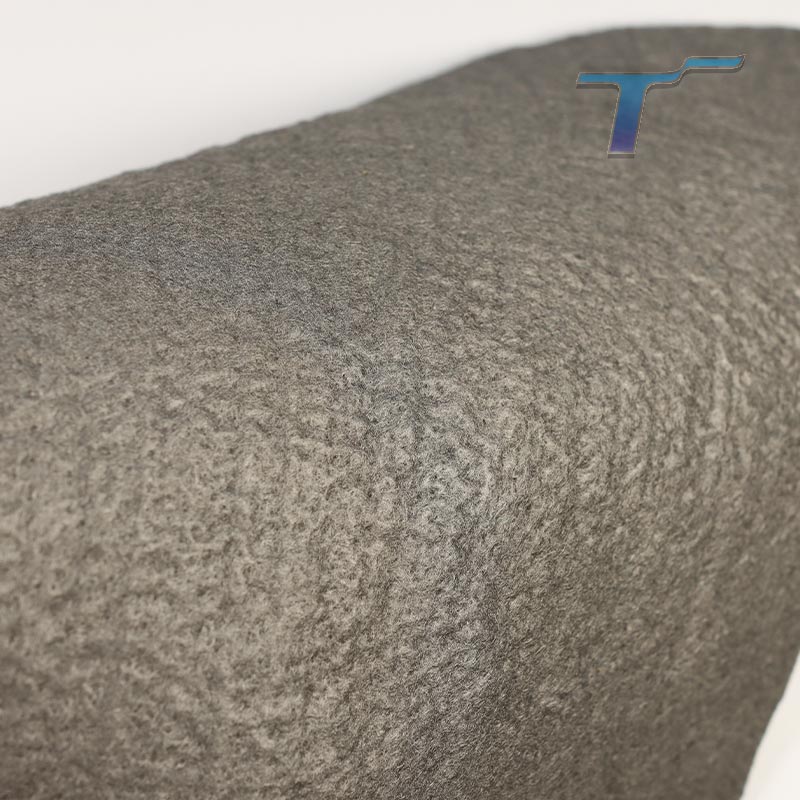

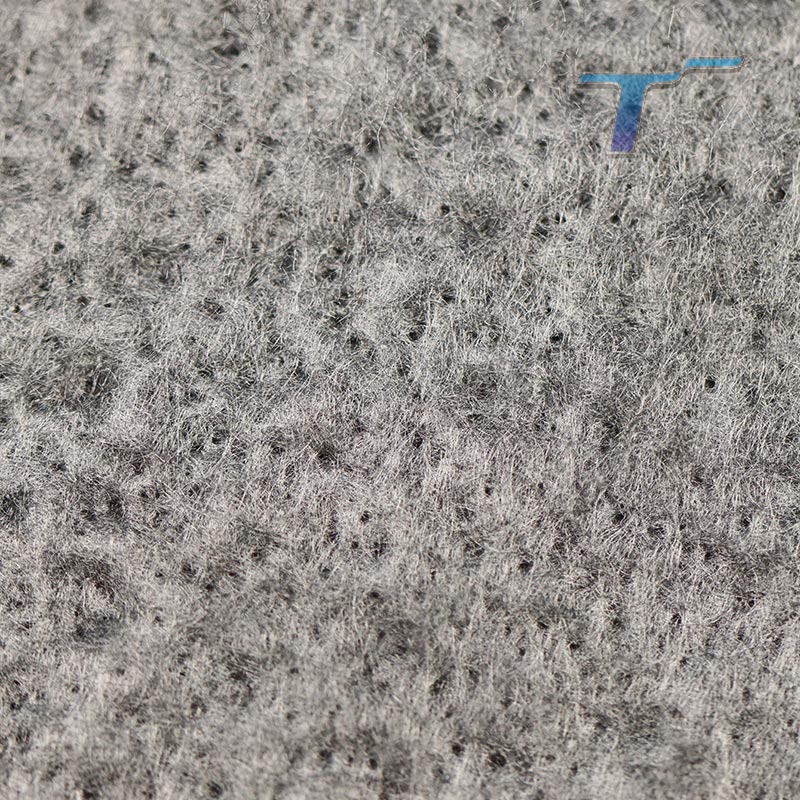

The main characteristics of stainless steel fiber needled felt (non-woven felt) are high melting point, high temperature resistance, corrosion resistance, softness, low resistance, good thermal conductivity and so on.

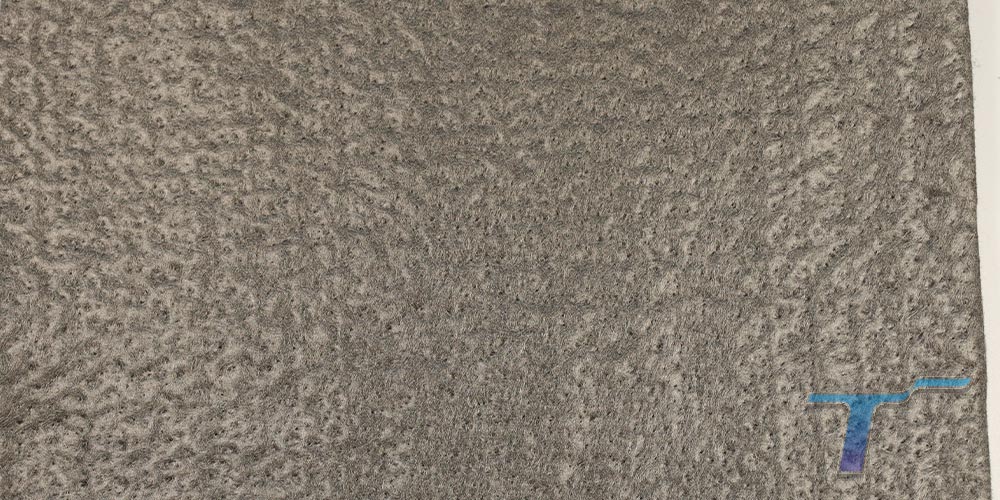

Specifications:

Thickness: 4mm

Gram weight: 1500g/㎡

Width: 1000mm / 1500mm

Thickness and weight can be customized according to requirements.

At present, it is mostly used in the glass industry in the production process of glass and mold separator and buffer materials. High temperature resistant suction cups in the production of bottle glass. It can also be applied to other materials that need to operate in a long-term high temperature environment.

Can be cut and customized according to the required specifications.

Peculiarity:

● High temperature resistant (>650 degrees Celsius)

● Smooth and soft surface

● Acid and alkali resistance, suitable for a variety of harsh environments

● Friction resistance

● Resistant to cleaning

● High breathability

Stainless steel fiber needled punch felt (non woven felt) is widely used in the glass industry (automotive glass, tempered glass, bottles and cans, etc.) mold coating and buffer materials. In the production process, the glass and the mold are perfectly separated, reducing vibration, reducing glass cracks and scratches.

Stainless steel fiber needled punch felt can also be made into suction cups and irregular shape used in high temperature environment mechanical arm buffer material.

Applications such as gaskets in long-term high temperature working environments.

● High temperature resistant (>650 degrees Celsius)

● Smooth and soft surface

● Acid and alkali resistance, suitable for a variety of harsh environments

● Friction resistance

● Resistant to cleaning

● High breathability